COMPANY INTRODUCTION

“TNS-INTEC” Company develops and implements the major innovative projects throughout the entire territory of the RoK and former Soviet Union:

- Automatic process control system and automatic control systems in oil and gas industry and production sector;

- Automated systems of commercial accounting of energy commodities of the telemetry system in energetic and community facilities;

- Automated control systems on rolling stock (railway, vehicle, waterborne traffic);

- Railway automation system on the base of advanced microprocessor technology.

We provide the innovative solutions of private and complex tasks of automation to our clients having improved the efficiency of production processes and provided the transition to new development level.

ACTIVITIES

The main direction of the EOG directory activity is development and implementation of projects of automation of technological processes in energy and oil and gas industry, as well as maintenance service of implemented systems.

Experience and knowledge of specialists enable to realize projects of different complexity and scale at a high professional level:

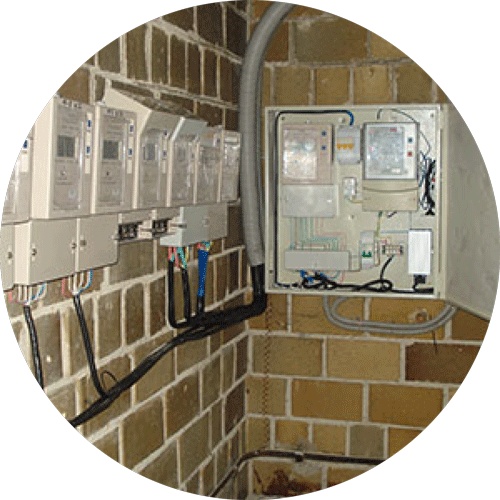

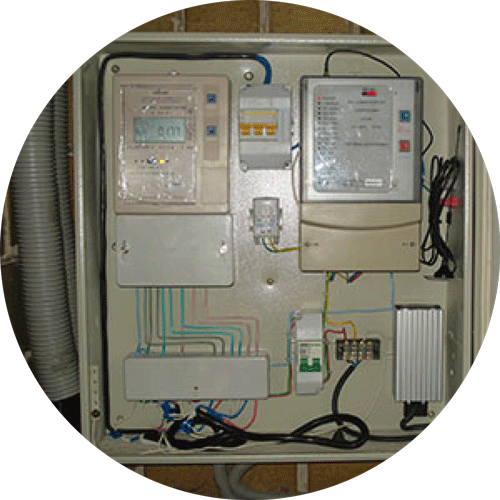

- automated systems of commercial accounting of electric energy (ASCAE) of a wholesale and retail market of electric energy;

- telemechanics systems;

- automated management systems of technological processes (AMSTP);

- automatic management systems (AMS);

-

dispatch control and management systems (SCADA).

At the moment one of the key projects under realization by the directory is the project on implementation of Intelligent control stations of oil production wells for the JSC “Ozenmunaygaz”.

For a short period of time a considerable complex of works was carried out: technical solution was worked out, production of Intelligent control stations was adjusted, specialists of the directory developed software of the system, equipment of wells is assembled and adjusted rapidly. As the result it is a unique product, which does not have analogues not only in Kazakhstan but also abroad. In spite of a very short period of time of operation, the system already now at the stage of implementation gives positive effect for the Customer; enabling to increase volumes of oil production, decrease electric energy consumption, operational costs, which eventually increases profitability of oil production.

Specialists of EOG directory successfully realized a number of key projects for national companies of the RK and private enterprises, for example:

- Telemechanics system of a linear part of oil pipelines of Western and Eastern branches of the JSC “KazTransOil”;

- System of accounting of oil debit of the JSC “Ozenmunaygaz”;

- ASCAE of a whole market of electric energy (WME) of the JSC “National company “Kazakhstan Temir Zholy”. The system was implemented on 20 out of 22 distances of electric supply, i.e. approximately on 91% of all power facilities of KTZ on the whole territory of the RK.

- ASCAE of a wholesale market of electric energy (WME) and telemechanics of power facilities of the JSC “Turgai Petroleum”

- ASCAE of a wholesale market of electric energy (WME) of the JSC “Petro Kazakhstan Kumkol Resources”

- System of automatics of the Point of oil heating and boiler facilities of HOPS named after Kassymov Atyrau city JSC “KazTransOil”

- ASCAE of a retail market of electric energy (RME) of Karagandy city (1500 transformer sub-stations, more than 150 thousand points of accounting of electric energy)

- and others.

AUTOMATION OF SYSTEMS IN ENERGY AND OIL AND GAS INDUSTRY

The main direction of the EOG directory activity is development and implementation of projects of automation of technological processes in energy and oil and gas industry, as well as maintenance service of implemented systems.

Experience and knowledge of specialists enable to realize projects of different complexity and scale at a high professional level:

- automated systems of commercial accounting of electric energy (ASCAE) of a wholesale and retail market of electric energy;

- telemechanics systems;

- automated management systems of technological processes (AMSTP);

- automatic management systems (AMS);

-

dispatch control and management systems (SCADA).

At the moment one of the key projects under realization by the directory is the project on implementation of Intelligent control stations of oil production wells for the JSC “Ozenmunaygaz”.

For a short period of time a considerable complex of works was carried out: technical solution was worked out, production of Intelligent control stations was adjusted, specialists of the directory developed software of the system, equipment of wells is assembled and adjusted rapidly. As the result it is a unique product, which does not have analogues not only in Kazakhstan but also abroad. In spite of a very short period of time of operation, the system already now at the stage of implementation gives positive effect for the Customer; enabling to increase volumes of oil production, decrease electric energy consumption, operational costs, which eventually increases profitability of oil production.

Specialists of EOG directory successfully realized a number of key projects for national companies of the RK and private enterprises, for example:

- Telemechanics system of a linear part of oil pipelines of Western and Eastern branches of the JSC “KazTransOil”;

- System of accounting of oil debit of the JSC “Ozenmunaygaz”;

- ASCAE of a whole market of electric energy (WME) of the JSC “National company “Kazakhstan Temir Zholy”. The system was implemented on 20 out of 22 distances of electric supply, i.e. approximately on 91% of all power facilities of KTZ on the whole territory of the RK.

- ASCAE of a wholesale market of electric energy (WME) and telemechanics of power facilities of the JSC “Turgai Petroleum”

- ASCAE of a wholesale market of electric energy (WME) of the JSC “Petro Kazakhstan Kumkol Resources”

- System of automatics of the Point of oil heating and boiler facilities of HOPS named after Kassymov Atyrau city JSC “KazTransOil”

- ASCAE of a retail market of electric energy (RME) of Karagandy city (1500 transformer sub-stations, more than 150 thousand points of accounting of electric energy)

- and others.

The main direction of the EOG directory activity is development and implementation of projects of automation of technological processes in energy and oil and gas industry, as well as maintenance service of implemented systems.

Experience and knowledge of specialists enable to realize projects of different complexity and scale at a high professional level:

- automated systems of commercial accounting of electric energy (ASCAE) of a wholesale and retail market of electric energy;

- telemechanics systems;

- automated management systems of technological processes (AMSTP);

- automatic management systems (AMS);

-

dispatch control and management systems (SCADA).

At the moment one of the key projects under realization by the directory is the project on implementation of Intelligent control stations of oil production wells for the JSC “Ozenmunaygaz”.

For a short period of time a considerable complex of works was carried out: technical solution was worked out, production of Intelligent control stations was adjusted, specialists of the directory developed software of the system, equipment of wells is assembled and adjusted rapidly. As the result it is a unique product, which does not have analogues not only in Kazakhstan but also abroad. In spite of a very short period of time of operation, the system already now at the stage of implementation gives positive effect for the Customer; enabling to increase volumes of oil production, decrease electric energy consumption, operational costs, which eventually increases profitability of oil production.

Specialists of EOG directory successfully realized a number of key projects for national companies of the RK and private enterprises, for example:

- Telemechanics system of a linear part of oil pipelines of Western and Eastern branches of the JSC “KazTransOil”;

- System of accounting of oil debit of the JSC “Ozenmunaygaz”;

- ASCAE of a whole market of electric energy (WME) of the JSC “National company “Kazakhstan Temir Zholy”. The system was implemented on 20 out of 22 distances of electric supply, i.e. approximately on 91% of all power facilities of KTZ on the whole territory of the RK.

- ASCAE of a wholesale market of electric energy (WME) and telemechanics of power facilities of the JSC “Turgai Petroleum”

- ASCAE of a wholesale market of electric energy (WME) of the JSC “Petro Kazakhstan Kumkol Resources”

- System of automatics of the Point of oil heating and boiler facilities of HOPS named after Kassymov Atyrau city JSC “KazTransOil”

- ASCAE of a retail market of electric energy (RME) of Karagandy city (1500 transformer sub-stations, more than 150 thousand points of accounting of electric energy)

- and others.

AUTOMATION OF SYSTEMS ON RAILWAY TRANSPORT

The largest innovative project, implemented by the directory is development of the ACS EDH – automated control sy...

The main direction of the EOG directory activity is development and implementation of projects of automation of technological processes in energy and oil and gas industry, as well as maintenance service of implemented systems.

Experience and knowledge of specialists enable to realize projects of different complexity and scale at a high professional level:

- automated systems of commercial accounting of electric energy (ASCAE) of a wholesale and retail market of electric energy;

- telemechanics systems;

- automated management systems of technological processes (AMSTP);

- automatic management systems (AMS);

-

dispatch control and management systems (SCADA).

At the moment one of the key projects under realization by the directory is the project on implementation of Intelligent control stations of oil production wells for the JSC “Ozenmunaygaz”.

For a short period of time a considerable complex of works was carried out: technical solution was worked out, production of Intelligent control stations was adjusted, specialists of the directory developed software of the system, equipment of wells is assembled and adjusted rapidly. As the result it is a unique product, which does not have analogues not only in Kazakhstan but also abroad. In spite of a very short period of time of operation, the system already now at the stage of implementation gives positive effect for the Customer; enabling to increase volumes of oil production, decrease electric energy consumption, operational costs, which eventually increases profitability of oil production.

Specialists of EOG directory successfully realized a number of key projects for national companies of the RK and private enterprises, for example:

- Telemechanics system of a linear part of oil pipelines of Western and Eastern branches of the JSC “KazTransOil”;

- System of accounting of oil debit of the JSC “Ozenmunaygaz”;

- ASCAE of a whole market of electric energy (WME) of the JSC “National company “Kazakhstan Temir Zholy”. The system was implemented on 20 out of 22 distances of electric supply, i.e. approximately on 91% of all power facilities of KTZ on the whole territory of the RK.

- ASCAE of a wholesale market of electric energy (WME) and telemechanics of power facilities of the JSC “Turgai Petroleum”

- ASCAE of a wholesale market of electric energy (WME) of the JSC “Petro Kazakhstan Kumkol Resources”

- System of automatics of the Point of oil heating and boiler facilities of HOPS named after Kassymov Atyrau city JSC “KazTransOil”

- ASCAE of a retail market of electric energy (RME) of Karagandy city (1500 transformer sub-stations, more than 150 thousand points of accounting of electric energy)

- and others.

The main direction of the EOG directory activity is development and implementation of projects of automation of technological processes in energy and oil and gas industry, as well as maintenance service of implemented systems.

Experience and knowledge of specialists enable to realize projects of different complexity and scale at a high professional level:

- automated systems of commercial accounting of electric energy (ASCAE) of a wholesale and retail market of electric energy;

- telemechanics systems;

- automated management systems of technological processes (AMSTP);

- automatic management systems (AMS);

-

dispatch control and management systems (SCADA).

At the moment one of the key projects under realization by the directory is the project on implementation of Intelligent control stations of oil production wells for the JSC “Ozenmunaygaz”.

For a short period of time a considerable complex of works was carried out: technical solution was worked out, production of Intelligent control stations was adjusted, specialists of the directory developed software of the system, equipment of wells is assembled and adjusted rapidly. As the result it is a unique product, which does not have analogues not only in Kazakhstan but also abroad. In spite of a very short period of time of operation, the system already now at the stage of implementation gives positive effect for the Customer; enabling to increase volumes of oil production, decrease electric energy consumption, operational costs, which eventually increases profitability of oil production.

Specialists of EOG directory successfully realized a number of key projects for national companies of the RK and private enterprises, for example:

- Telemechanics system of a linear part of oil pipelines of Western and Eastern branches of the JSC “KazTransOil”;

- System of accounting of oil debit of the JSC “Ozenmunaygaz”;

- ASCAE of a whole market of electric energy (WME) of the JSC “National company “Kazakhstan Temir Zholy”. The system was implemented on 20 out of 22 distances of electric supply, i.e. approximately on 91% of all power facilities of KTZ on the whole territory of the RK.

- ASCAE of a wholesale market of electric energy (WME) and telemechanics of power facilities of the JSC “Turgai Petroleum”

- ASCAE of a wholesale market of electric energy (WME) of the JSC “Petro Kazakhstan Kumkol Resources”

- System of automatics of the Point of oil heating and boiler facilities of HOPS named after Kassymov Atyrau city JSC “KazTransOil”

- ASCAE of a retail market of electric energy (RME) of Karagandy city (1500 transformer sub-stations, more than 150 thousand points of accounting of electric energy)

- and others.

SECURITY SYSTEM ON RAILWAYS

SIGNALING, CENTRALIZATION, BLOCKING

SCB – signaling, centralization, blocking of points and signals of participants of the railway.

The main type of a...

The main direction of the EOG directory activity is development and implementation of projects of automation of technological processes in energy and oil and gas industry, as well as maintenance service of implemented systems.

Experience and knowledge of specialists enable to realize projects of different complexity and scale at a high professional level:

- automated systems of commercial accounting of electric energy (ASCAE) of a wholesale and retail market of electric energy;

- telemechanics systems;

- automated management systems of technological processes (AMSTP);

- automatic management systems (AMS);

-

dispatch control and management systems (SCADA).

At the moment one of the key projects under realization by the directory is the project on implementation of Intelligent control stations of oil production wells for the JSC “Ozenmunaygaz”.

For a short period of time a considerable complex of works was carried out: technical solution was worked out, production of Intelligent control stations was adjusted, specialists of the directory developed software of the system, equipment of wells is assembled and adjusted rapidly. As the result it is a unique product, which does not have analogues not only in Kazakhstan but also abroad. In spite of a very short period of time of operation, the system already now at the stage of implementation gives positive effect for the Customer; enabling to increase volumes of oil production, decrease electric energy consumption, operational costs, which eventually increases profitability of oil production.

Specialists of EOG directory successfully realized a number of key projects for national companies of the RK and private enterprises, for example:

- Telemechanics system of a linear part of oil pipelines of Western and Eastern branches of the JSC “KazTransOil”;

- System of accounting of oil debit of the JSC “Ozenmunaygaz”;

- ASCAE of a whole market of electric energy (WME) of the JSC “National company “Kazakhstan Temir Zholy”. The system was implemented on 20 out of 22 distances of electric supply, i.e. approximately on 91% of all power facilities of KTZ on the whole territory of the RK.

- ASCAE of a wholesale market of electric energy (WME) and telemechanics of power facilities of the JSC “Turgai Petroleum”

- ASCAE of a wholesale market of electric energy (WME) of the JSC “Petro Kazakhstan Kumkol Resources”

- System of automatics of the Point of oil heating and boiler facilities of HOPS named after Kassymov Atyrau city JSC “KazTransOil”

- ASCAE of a retail market of electric energy (RME) of Karagandy city (1500 transformer sub-stations, more than 150 thousand points of accounting of electric energy)

- and others.

AUTOMATION OF MUDFLOW AND AVALANCHE HAZARD MONITORING SYSTEMS

“Automated mudflow hazard monitoring system in the Kishi and Ulken Almaty, Kargaly and Aksai river basins”.

Automation of mudflow and avalanche hazard monitoring systems

Currently, a microprocessor-based automation and telemechanics system is under construction within the framework of the project “Automated mudflow hazard monitoring system in the Kishi and Ulken Almaty, Kargaly and Aksai river basins”.

The automated monitoring system for mudflow hazard AFM includes the following components:

- a complex of measuring and automation tools, which includes analog and discrete sensors for monitoring natural parameters, sensors for detecting changes in the environment; monitoring cabinets.

- a data transmission network, which includes equipment and devices for transmitting information via wired and wireless communications;

- an automated system for dispatching monitoring of objects, which includes a network for collecting information from local monitoring stations, input / output servers, computer workstations of dispatchers, software systems.

Monitoring stations are intended for regular measurement, analysis and forecasting of characteristics indicating the possibility of mudflow formation, monitoring the course of the mudflow process, early warning of the threat or occurrence of mudflows of the population and emergency services. Early warning will allow you to take preventive measures to localize, suppress or minimize the possible level of hazardous factors, and organize emergency rescue operations in a timely manner.

The AFM system of this project includes 31 monitoring stations, which are divided by their location into 5 types:

Lake monitoring stations (8 units on moraine-glacial lakes).

Focal monitoring stations (7 pcs. In mudflow foci).

Channel monitoring stations (11 pcs. In mudflow riverbeds).

Dam monitoring stations (5 pcs. On mudflow protection dams).

Central control room with a server for collecting and processing data and an automatic workstation (AWP) of the operator (dispatcher) for monitoring emergencies.

SERVICES

Produced services - turnkey project

prospecting works and survey of facilities

development of a design estimate documentation with state appraisal

development of software

supply of equipment of leading world producers

production of modular-packaged units of automation with certification in the rk

construction assembly works

start-up and commissioning works

training of a customer’s personnel

commissioning of systems

sarranty and maintenance service

аutomation of oil depots

TNS-INTEC PROJECTS

AUTOMATED CONTROL SYSTEM FOR “ENERGY DISPATCHING TRACTION”

| Customer: | “Transtelecom” JSC |

| Implementation year: | 2012 - 2015 |

Immensity

About 632 locomotives and 311 electromotives are equipped with the system. The works for assembly and adjusting have been performed on 12 locomotives bases and 5 electromotive overhaul bases throughout the whole territory of the Republic of Kazakhstan.

Scope of works and services provided

Implementation of the ACS EDT was performed on a turnkey basis with further service backup during the whole period of the long-term contract, which includes the software engineering, supply of service hardware, installation of information accumulation points in engine houses and points of locomotive crew leisure, development of personal devices for data gathering of machinists and airborne equipment of locomotives.

Core of the project

Primary purpose of ACS EDT is all-round automation and informational support of business processes for accounting, control and demand analysis of: electric energy (expendable for hauling operations and electrical heating of passenger carriages) and diesel fuel (expendable by locomotive during servicing and exploitation at all types of work) in real-time mode.

Unicity

The locomotives and electromotives of the “Locomotiv” JSC were equipped with high-accuracy unique measurement tools of diesel fuel consumption record and electric power consumption. By virtue of innovative technology implementation and efficient use of the fuel and power resources the Customer could not only improve efficiency of railway traffic having reduced the power consumption in hauling operations, but also improve the management structure of energy complex using the most workable technologies at the moment.

Obtained result

-

Implementation of the ACS EDT was enabled the Customer to achieve the following opportunities:

-

Measurement of operational parameters of fuel facility and diesel-generator set.

-

Calculation with specified accuracy of residual fuel and diesel fuel consumption for definite period of time

-

Control and comparison of real consumption of diesel fuel/electric energy with standard values during various operating modes of locomotive/electromotive

-

Indirect diagnostics of fuel facility based on data of fuel consumption at various operating modes; Performance analysis of locomotive/electromotive per shift with separation of time periods;

-

stop and movement;

-

diesel operation at idle, under load and shut-down, motion characteristic of locomotive/electromotive in the mode of haulage and run-down;

-

haulage, average running speed along the section;

-

total fuel and electric energy consumption for journey, shift, period along the section;

-

location of locomotive/electromotive;

-

information visualization for process values of fuel facility and diesel-generator set (on the locomotive);

-

formation of electronic machinist route in the scope of locomotive process values collected by the sensors, information input from the block;

-

machinist visualization from remote terminals;

-

run between repairs of locomotives.

«transtelecom» jsc

Primary purpose of ACS EDT is all-round automation and informational support of business processes for accounting, control and demand analysis of: ele...

AUTOMATED CONTROL SYSTEM FOR “ENERGY DISPATCHING TRACTION”

| Customer: | “Transtelecom” JSC |

| Implementation year: | 2012 - 2015 |

Immensity

About 632 locomotives and 311 electromotives are equipped with the system. The works for assembly and adjusting have been performed on 12 locomotives bases and 5 electromotive overhaul bases throughout the whole territory of the Republic of Kazakhstan.

Scope of works and services provided

Implementation of the ACS EDT was performed on a turnkey basis with further service backup during the whole period of the long-term contract, which includes the software engineering, supply of service hardware, installation of information accumulation points in engine houses and points of locomotive crew leisure, development of personal devices for data gathering of machinists and airborne equipment of locomotives.

Core of the project

Primary purpose of ACS EDT is all-round automation and informational support of business processes for accounting, control and demand analysis of: electric energy (expendable for hauling operations and electrical heating of passenger carriages) and diesel fuel (expendable by locomotive during servicing and exploitation at all types of work) in real-time mode.

Unicity

The locomotives and electromotives of the “Locomotiv” JSC were equipped with high-accuracy unique measurement tools of diesel fuel consumption record and electric power consumption. By virtue of innovative technology implementation and efficient use of the fuel and power resources the Customer could not only improve efficiency of railway traffic having reduced the power consumption in hauling operations, but also improve the management structure of energy complex using the most workable technologies at the moment.

Obtained result

-

Implementation of the ACS EDT was enabled the Customer to achieve the following opportunities:

-

Measurement of operational parameters of fuel facility and diesel-generator set.

-

Calculation with specified accuracy of residual fuel and diesel fuel consumption for definite period of time

-

Control and comparison of real consumption of diesel fuel/electric energy with standard values during various operating modes of locomotive/electromotive

-

Indirect diagnostics of fuel facility based on data of fuel consumption at various operating modes; Performance analysis of locomotive/electromotive per shift with separation of time periods;

-

stop and movement;

-

diesel operation at idle, under load and shut-down, motion characteristic of locomotive/electromotive in the mode of haulage and run-down;

-

haulage, average running speed along the section;

-

total fuel and electric energy consumption for journey, shift, period along the section;

-

location of locomotive/electromotive;

-

information visualization for process values of fuel facility and diesel-generator set (on the locomotive);

-

formation of electronic machinist route in the scope of locomotive process values collected by the sensors, information input from the block;

-

machinist visualization from remote terminals;

-

run between repairs of locomotives.

SYSTEM OF TRAIN SEPARATION FOR TRAIN TRAFFIC IN SEGMENT OF KANDYAGASH-NIKELTAU RAILWAY LINE

| Customer: | “NC “Kazakhstan Temir Zholy” JSC |

| Implementation year: | 2013-2015 |

Immensity

Kandygash-Nikeltau section with the length of 136,1 km

Scope of works and services rendered

Within the project was performed the package of services including the building and assembly works at all stations and running lines of Kandygash-Nikeltau railroad section, installation and erection procedure, adjustment work and test works, training of production operating personnel to directions for use and service of newly input devices.

Core of the project

The primary purpose of the system is provision of security and trains traffic arrangements on the Kandyagash-Nikeltau railroad section

Unicity

For solution of tasks set by the Customer the complex of devices necessary for performing functions for systems of interlocking, alarm, dispatch control and movement control. By virtue of stepwise section modernization, none of interim stages has not appeared as a cause of failure in operation of current or allied systems, and by contrast promoted the section capacity growth, increase of speed and enhancement of train movements safety. The first results of the system implementation have provided the positive effects in as little as three months after agreement.

Obtained result

- The current system has enabled the Customer in provision of:

- Growth of carrying capacity of section and enhancement of trains movement safety

- at the expense of equipage of signal box and stations with control units for tracks vacancy on adjacent running lines;

- Enhancement of traffic safety;

- Growth of motion speed by virtue of transfer to the locomotive of expanded amount of information;

- Decrease of operating costs and enhancement of operating management flexibility;

- Load decrease to the work of station duty officers;

- Optimization of energy resources necessary for driving of train;

- Enhancement of flexibility during organization of train traffic as well as provision of advanced functions to production supervisors.

“nc “kazakhstan temir zholy” jsc

The primary purpose of the system is provision of security and trains traffic arrangements on the Kandyagash-Nikeltau railroad section...

SYSTEM OF TRAIN SEPARATION FOR TRAIN TRAFFIC IN SEGMENT OF KANDYAGASH-NIKELTAU RAILWAY LINE

| Customer: | “NC “Kazakhstan Temir Zholy” JSC |

| Implementation year: | 2013-2015 |

Immensity

Kandygash-Nikeltau section with the length of 136,1 km

Scope of works and services rendered

Within the project was performed the package of services including the building and assembly works at all stations and running lines of Kandygash-Nikeltau railroad section, installation and erection procedure, adjustment work and test works, training of production operating personnel to directions for use and service of newly input devices.

Core of the project

The primary purpose of the system is provision of security and trains traffic arrangements on the Kandyagash-Nikeltau railroad section

Unicity

For solution of tasks set by the Customer the complex of devices necessary for performing functions for systems of interlocking, alarm, dispatch control and movement control. By virtue of stepwise section modernization, none of interim stages has not appeared as a cause of failure in operation of current or allied systems, and by contrast promoted the section capacity growth, increase of speed and enhancement of train movements safety. The first results of the system implementation have provided the positive effects in as little as three months after agreement.

Obtained result

- The current system has enabled the Customer in provision of:

- Growth of carrying capacity of section and enhancement of trains movement safety

- at the expense of equipage of signal box and stations with control units for tracks vacancy on adjacent running lines;

- Enhancement of traffic safety;

- Growth of motion speed by virtue of transfer to the locomotive of expanded amount of information;

- Decrease of operating costs and enhancement of operating management flexibility;

- Load decrease to the work of station duty officers;

- Optimization of energy resources necessary for driving of train;

- Enhancement of flexibility during organization of train traffic as well as provision of advanced functions to production supervisors.

INTELLECTUAL STATION FOR MANAGEMENT OF BAR-DEEP WATER PUMP UNITS MANAGEMENT

| Customer: | “OzenMunaiGaz” JSC |

| Implementation year: | 2014 |

Immensity

300 wells sites allocated by all 12 oil fields of Zhanaozen city

Scope of works and services rendered

Our professionals have performed the full package of services, including the sites survey, production and supply of equipment, pre-commissioning activities as well as Customer personnel training and systems commissioning to commercial operation.

Core of projects

ICS SRPU is designed for remote control and operation mode control as well as operation modes optimization for sucker-rod pumping units for crude production with communication of information to dispatch stations using GSM-technologies.

Unicity

ICS SRPU was developed by the “TNS-INTEC” LLP specialists and being the certified of Kazakhstan product (CT-KZ). The unique software for which there are no analogous in neither Kazakhstan nor foreign countries was established for this system. Within the contract framework 300 well sites allocated by all 12 oil fields of Zhanaozen town have been upgraded.

Obtained result

The implemented system has allowed achieving the effective results such as:

- Energy saving;

- Remote supervision and management of operational parameters of SRPU;

- Control automation for SPRU motor drive;

- Equipment operation maintenance on the basis of mode and adjusting capacity under variable conditions of system;

- Optimization of well operation mode;

- Increase of workover interval of downhole equipment;

- Operational detection of equipment emergency response;

- Decrease of electric installation and pumps wear at the expense of gentle start, multiple reduction of inrush current value;

- Unification of ICS (opportunity of working with any types of pumping equipment (SRPU, ESP units) and types of electric motors (asynchronous and synchronous);

- Improvement and facilitation of operation conditions of auxiliary personnel, reduction of operating costs;

- Increase of oil flow rate

The primary and important point in the project is that the Customer has obtained the rise in profitability of oil recovery at the expense of reduction in operating costs, primarily energy, rise of oil recovery and increase of overhaul life.

“ozenmunaigaz” jsc

ICS SRPU is designed for remote control and operation mode control as well as operation modes optimization for sucker-rod pumping units for crude pro...

INTELLECTUAL STATION FOR MANAGEMENT OF BAR-DEEP WATER PUMP UNITS MANAGEMENT

| Customer: | “OzenMunaiGaz” JSC |

| Implementation year: | 2014 |

Immensity

300 wells sites allocated by all 12 oil fields of Zhanaozen city

Scope of works and services rendered

Our professionals have performed the full package of services, including the sites survey, production and supply of equipment, pre-commissioning activities as well as Customer personnel training and systems commissioning to commercial operation.

Core of projects

ICS SRPU is designed for remote control and operation mode control as well as operation modes optimization for sucker-rod pumping units for crude production with communication of information to dispatch stations using GSM-technologies.

Unicity

ICS SRPU was developed by the “TNS-INTEC” LLP specialists and being the certified of Kazakhstan product (CT-KZ). The unique software for which there are no analogous in neither Kazakhstan nor foreign countries was established for this system. Within the contract framework 300 well sites allocated by all 12 oil fields of Zhanaozen town have been upgraded.

Obtained result

The implemented system has allowed achieving the effective results such as:

- Energy saving;

- Remote supervision and management of operational parameters of SRPU;

- Control automation for SPRU motor drive;

- Equipment operation maintenance on the basis of mode and adjusting capacity under variable conditions of system;

- Optimization of well operation mode;

- Increase of workover interval of downhole equipment;

- Operational detection of equipment emergency response;

- Decrease of electric installation and pumps wear at the expense of gentle start, multiple reduction of inrush current value;

- Unification of ICS (opportunity of working with any types of pumping equipment (SRPU, ESP units) and types of electric motors (asynchronous and synchronous);

- Improvement and facilitation of operation conditions of auxiliary personnel, reduction of operating costs;

- Increase of oil flow rate

The primary and important point in the project is that the Customer has obtained the rise in profitability of oil recovery at the expense of reduction in operating costs, primarily energy, rise of oil recovery and increase of overhaul life.

LINE TELECONTROL SYSTEM OF MAIN PIPELINES

| Customer: | “KazTransOil” JSC |

| Implementation year: | 2013-2014 |

Immensity

Western and Eastern branches of the “KazTransOil” JSC. Implementation of linear system of telemechanics of main pipelines of the Western branch of the “KazTransOil” JSC was performed in Aktau, Atyrau, Kalamkas, Karazhanbas, Uzen and Samara. Eastern branch-in Shymkent, Pavlodar, Karakoin, Kumkol, Priirtyshsk.

Scope of works and services rendered

Technical experts of our company have performed the full package of works on a turnkey basis- survey work, development of design and estimate documentation and software, production and supply of equipment, assembly and precommissioning.

Core of the project

The system provides the supervisory monitoring of technological parameters of oil pipage and operating control for dampers on linear sections of main pipelines.

Unicity

The project unique in its immensity with the coverage of the most part of linear sections of oil pipelines of the “KazTransOil” JSC.

Obtained result

As a result of project implementation the Customer has enhanced the efficiency of production and economic company activity including at the expense of:

- Maximum security and operational integrity of oil pipelines;

- Opportunity of continuous inspection for equipment condition;

- Prompt attention to emergency response and opportunity of as soon as practicable localize it having blocked the problem areas.

“kaztransoil” jsc

The system provides the supervisory monitoring of technological parameters of oil pipage and operating control for dampers on linear sections of main...

LINE TELECONTROL SYSTEM OF MAIN PIPELINES

| Customer: | “KazTransOil” JSC |

| Implementation year: | 2013-2014 |

Immensity

Western and Eastern branches of the “KazTransOil” JSC. Implementation of linear system of telemechanics of main pipelines of the Western branch of the “KazTransOil” JSC was performed in Aktau, Atyrau, Kalamkas, Karazhanbas, Uzen and Samara. Eastern branch-in Shymkent, Pavlodar, Karakoin, Kumkol, Priirtyshsk.

Scope of works and services rendered

Technical experts of our company have performed the full package of works on a turnkey basis- survey work, development of design and estimate documentation and software, production and supply of equipment, assembly and precommissioning.

Core of the project

The system provides the supervisory monitoring of technological parameters of oil pipage and operating control for dampers on linear sections of main pipelines.

Unicity

The project unique in its immensity with the coverage of the most part of linear sections of oil pipelines of the “KazTransOil” JSC.

Obtained result

As a result of project implementation the Customer has enhanced the efficiency of production and economic company activity including at the expense of:

- Maximum security and operational integrity of oil pipelines;

- Opportunity of continuous inspection for equipment condition;

- Prompt attention to emergency response and opportunity of as soon as practicable localize it having blocked the problem areas.

AUTOMATIC SYSTEM FOR COMMERCIAL ACCOUNTING OF POWER CONSUMPTION OF THE “NC “KAZAKHSTAN TEMIR ZHOLY” JSC

| Customer: | “NC “Kazakhstan Temir Zholy” JSC |

| Implementation year: | 2006 – 2013 |

Immensity

The whole territory of the Republic of Kazakhstan

Scope of works and services rendered

The company technical experts have conducted the full complex of services- inspection, development and approval of design and estimate documentation, delivery and installation of equipment, commissioning, training of the Customer staff as well as systems handover to commercial operation.

Core of the project

ASCAPC represents the complex of technical, software and organizational decisions enabling the consumer to keep accounts of electricity consumption as required by the RoK Law “Concerning the Electric Power Industry”. The system is designed for automation of process of data acquisition on consumption of the “NC “Kazakhstan Temir Zholy” JSC from all facilities affording an opportunity to monitor the accuracy of energy accounting and rapidly obtain the data on the balance of electric output of electrical energy.

Unicity

The project is a globally-distributed system with 22 branches throughout the whole territory of the Republic of Kazakhstan. It is the first project of such scale in the Republic and CIS countries. The maximum number of existing modes of communication of the “NC “Kazakhstan Temir Zholy” JSC from cable wires to satellite communication channels has been involved within the frameworks of a project.

Obtained result

The current system has enabled the Customer to provide:

- Automation of control and accounting of electrical power sales;

- Precise determination of quantity of supplied and consumable electrical energy;

- Decrease in electric energy loss at the expense of continuous monitoring during its transmission and distribution;

- Improving accuracy of commercial accounting of electric energy in accounting points according to the requirements of the Kazakhstani wholesale electricity market using advanced devices, application of digital technology, data acquisition and processing;

- Reduction in maintenance cost;

- Improvement of quality and reliability of electric power supply;

- Provision of commercial accounting measurements synchronism;

- Improving reliability of commercial accounting system and information protection at all levels by means of technical, software and organizational solutions applied in the system;

- Implementation of single information support system for carrying out of the Customer financial arrangement at the RoK wholesale electricity market.

“nc “kazakhstan temir zholy” jsc

ASCAPC represents the complex of technical, software and organizational decisions enabling the consumer to keep accounts of electricity consumption as...

АВТОМАТИЗИРОВАННАЯ СИСТЕМА КОММЕРЧЕСКОГО УЧЁТА ЭЛЕКТРОЭНЕРГИИ БЫТОВОГО ПОТРЕБИТЕЛЯ

| Заказчик: | АО «НК «Қазақстан Темір Жолы» |

| Год реализации: | 2006 – 2013 |

Масштабность

Вся территория Республика Казахстан

Объём предоставленных работ и услуг

Технические специалисты компании провели полный комплекс услуг – обследование, разработку и утверждение проектно-сметной документации, поставку и установку оборудования, пуско-наладочные работы, обучение персонала заказчика, а также передачу систем в промышленную эксплуатацию.

Суть проекта

АСКУЭ представляет собой комплекс технических, программных и организационных решений, позволяющих потребителю вести учёт потребления электроэнергии в соответствии с требованиями Закона РК «Об Электроэнергетик

Уникальность

Проект является глобально-распре

Полученный результат

Действующая система позволила Заказчику обеспечить:

-

Автоматизацию контроля и учёта реализации электроэнергии;

-

Точное определение количества поставляемой и потребляемой электрической энергии;

-

Снижение потерь электроэнергии за счёт непрерывного контроля при её передаче и распределении;

-

Повышение точности коммерческого учёта электроэнергии в точках учёта согласно требованиям Казахстанского оптового рынка электроэнергии и мощности, за счёт использования современных приборов, применения цифровых технологий, сбора и обработки данных;

-

Снижение эксплутационных затрат;

-

Улучшение надёжности и качества снабжения электроэнергией;

-

Обеспечение синхронности измерений коммерческого учёта;

-

Повышение надёжности системы коммерческого учёта и защищенности информации на всех уровнях за счёт применяемых в системе технических, программных и организационных решений;

-

Создание системы единого информационного обеспечения для проведения финансовых расчетов Заказчика на оптовом рынке электроэнергии РК.

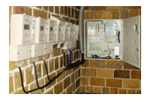

AUTOMATIC SYSTEM FOR COMMERCIAL ACCOUNTING OF POWER CONSUMPTION

| Customer: | “Karagandy Zharyk” LLP |

| Implementation year: | 2012-2014 |

Immensity

Karaganda

Scope of works and services rendered

Within the project, the expert of our company have performed the development and supply of requisite equipment, development of software, performed the commissioning and instructed the Customer company employees.

Core of the project

ASCAPC of the “Karagandy Zharyk” LLP is designed for automation of data acquisition on consumption of electrical energy by domestic consumers of Karaganda (private sector, apartment blocks) using PLC-technologies, automatic data processing and data communication in energy-supplying organizations for commercial considerations.

Unicity

The project immensity in the context of domestic customers coverage is unrivalled neither in Kazakhstan, nor in the CIS countries. The system provides the automatic data acquisition from more than 17 000 subscribers, covers 1500 transformer substations.

Obtained result

The current system has enabled the Customer to provide:

- The multiple tariff energy accounting;

- Accuracy increase for energy accounting;

- Optimization of electrical energy consumption mode;

- Generation of measurable parameters base and process data of obtained information with storage and archiving functions with storable life of at least five years;

- Maintenance of single system time for the purpose of minimization of nonmanufacturing costs for energy resources at the expense of provision of synchronous measurements;

- The visual image of information on receiving and supply of electric energy by accounting points in the form of tables, diagrams and mnemonic diagrams;

- Provision of calculations by adjustable calculation algorithms;

- Revealing of focuses with losses occurrence;

- Determination and forecasting (short-, medium and long-term) components of the electric energy balance for the purpose of time minimization for analysis of electrical energy consumption for further development of measures focused on power transmission process optimization;

- Improvement of effectiveness and efficient use of available resources;

- Cost saving from electrical energy loss enhancement at the level of 0,4 kWatt;

- Determination of electrical energy balance.

- Labor saving in terms of manual handling of information.

“karagandy zharyk” llp

ASCAPC of the “Karagandy Zharyk” LLP is designed for automation of data acquisition on consumption of electrical energy by domestic consumers of Karag...

AUTOMATIC SYSTEM FOR COMMERCIAL ACCOUNTING OF POWER CONSUMPTION

| Customer: | “Karagandy Zharyk” LLP |

| Implementation year: | 2012-2014 |

Immensity

Karaganda

Scope of works and services rendered

Within the project, the expert of our company have performed the development and supply of requisite equipment, development of software, performed the commissioning and instructed the Customer company employees.

Core of the project

ASCAPC of the “Karagandy Zharyk” LLP is designed for automation of data acquisition on consumption of electrical energy by domestic consumers of Karaganda (private sector, apartment blocks) using PLC-technologies, automatic data processing and data communication in energy-supplying organizations for commercial considerations.

Unicity

The project immensity in the context of domestic customers coverage is unrivalled neither in Kazakhstan, nor in the CIS countries. The system provides the automatic data acquisition from more than 17 000 subscribers, covers 1500 transformer substations.

Obtained result

The current system has enabled the Customer to provide:

- The multiple tariff energy accounting;

- Accuracy increase for energy accounting;

- Optimization of electrical energy consumption mode;

- Generation of measurable parameters base and process data of obtained information with storage and archiving functions with storable life of at least five years;

- Maintenance of single system time for the purpose of minimization of nonmanufacturing costs for energy resources at the expense of provision of synchronous measurements;

- The visual image of information on receiving and supply of electric energy by accounting points in the form of tables, diagrams and mnemonic diagrams;

- Provision of calculations by adjustable calculation algorithms;

- Revealing of focuses with losses occurrence;

- Determination and forecasting (short-, medium and long-term) components of the electric energy balance for the purpose of time minimization for analysis of electrical energy consumption for further development of measures focused on power transmission process optimization;

- Improvement of effectiveness and efficient use of available resources;

- Cost saving from electrical energy loss enhancement at the level of 0,4 kWatt;

- Determination of electrical energy balance.

- Labor saving in terms of manual handling of information.

AUTOMATIC SYSTEM FOR COMMERCIAL ACCOUNTING OF POWER CONSUMPTION AND TELEMECHANICS OF POWER FACILITIES AT THE KUMKOL FIELD

| Customer: | “Turgai-Petroleum” JSC |

| Implementation year: | 2008 – 2012 |

Immensity

Kyzylordinskaya oblast. Kumkol oil and gas field: 4 electric substations 110/6 kW, 11 distribution substations 6 kW.

Scope of works and services rendered

The company professionals have performed the works for development of design and estimate documentation and creation of record-keeping system at the “TURGAI-PETROLEUM” JSC facilities. In addition the following works have been performed: supply of equipment and software, assembly and precommissioning.

Core of the project

ASCAPC of the “TURGAI-PETROLEUM” JSC is an automated information source for commercial and technical record-keeping of electrical energy. The system makes the meaningful measurement of electrical energy in each record point, generates the data base of commercial accounting of energy generation and consumption by each record point, forms the calculation of actual balance of production-consumption of electric energy.

Obtained result

The current system has enabled the Customer to provide:

- The synchronism of measurements of commercial accounting for electrical energy by record points;

- Compulsory checking of electrical energy consumption and implementation of measures for energy saving and energy efficiency;

- Obtaining of possibility for application of energy-saving tariffs for calculations;

- Optimization of electrical energy use conditions;

- Improving accuracy in commercial accounting of electrical energy in record points using the advanced energy accounting meters and application of digital technology in measurements, data acquisition and processing;

- Carrying out of various electric engineering tasks (calculation of electrical energy balance for the entire enterprise and by separate power facilities, calculation of electrical energy losses in electric main) using the ASCAPC data.

“turgai-petroleum” jsc

ASCAPC of the “TURGAI-PETROLEUM” JSC is an automated information source for commercial and technical record-keeping of electrical energy. The system m..

AUTOMATIC SYSTEM FOR COMMERCIAL ACCOUNTING OF POWER CONSUMPTION AND TELEMECHANICS OF POWER FACILITIES AT THE KUMKOL FIELD

| Customer: | “Turgai-Petroleum” JSC |

| Implementation year: | 2008 – 2012 |

Immensity

Kyzylordinskaya oblast. Kumkol oil and gas field: 4 electric substations 110/6 kW, 11 distribution substations 6 kW.

Scope of works and services rendered

The company professionals have performed the works for development of design and estimate documentation and creation of record-keeping system at the “TURGAI-PETROLEUM” JSC facilities. In addition the following works have been performed: supply of equipment and software, assembly and precommissioning.

Core of the project

ASCAPC of the “TURGAI-PETROLEUM” JSC is an automated information source for commercial and technical record-keeping of electrical energy. The system makes the meaningful measurement of electrical energy in each record point, generates the data base of commercial accounting of energy generation and consumption by each record point, forms the calculation of actual balance of production-consumption of electric energy.

Obtained result

The current system has enabled the Customer to provide:

- The synchronism of measurements of commercial accounting for electrical energy by record points;

- Compulsory checking of electrical energy consumption and implementation of measures for energy saving and energy efficiency;

- Obtaining of possibility for application of energy-saving tariffs for calculations;

- Optimization of electrical energy use conditions;

- Improving accuracy in commercial accounting of electrical energy in record points using the advanced energy accounting meters and application of digital technology in measurements, data acquisition and processing;

- Carrying out of various electric engineering tasks (calculation of electrical energy balance for the entire enterprise and by separate power facilities, calculation of electrical energy losses in electric main) using the ASCAPC data.

AUTOMATED SYSTEM OF COMMERCIAL ACCOUNTING OF ELECTRIC ENERGY OF THE “PETROKAZAKHSTAN KUMKOL RESOURCES” JSC

| Customer: | “PetroKazakhstan Kumkol Resources” JSC |

| Implementation year: | 2007 – 2015 |

Immensity

Kyzylordinskaya oblast. Kumkol oil and gas field.

Scope of works and services rendered

The company professionals have performed the development of design and estimate documentation, supply of equipment, performed the construction and assembly and pre-commissioning activities.

Core of the project

ASCAPC of the “PetroKazakhstan Kumkol Resources” JSC is an automatic information source for commercial accounting of electric power and capacity. The system generates the data base of commercial accounting for energy generation and consumption by each record point, calculates the actual balance of production and consumption of electrical energy as well as provides the unbiased information for management of distribution of electricity and power.

Project unicity

ASCAPC of the “PetroKazakhstan Kumkol Resources” JSC was put in commercial operation and registered in the Register of electric power fiscal metering system of the wholesale electricity market of the Republic of Kazakhstan.

The long term of the project implementation was conditioned by the reason that the system implementation has been performed in several steps. First power facilities of the Kumkol oil-gas field were equipped in 2007, after which the Customer having assessed the advantages of operation with new system annually automatizes the new projects under construction.

Obtained result

The current system has enables the Customer to provide:

- The acquisition and delivery of information according to regulations, processing and issue of ASCAPC information in real time to the “PetroKazakhstan Kumkol Resources” JSC personnel as well as acquisition and delivery of information upon the request at all times;

- Obtaining of reliable and legitimate electricity metering in each record point using measuring devices;

- Enhanced accuracy of commercial accounting of electrical energy in record points using advanced energy accounting meters and application of digital technology of measurements, data acquisition and processing;

- Calculation of electrical energy balance for entire enterprise and by separate power facilities;

- Calculation of electrical energy losses in electric main using the ASCAPC data;

- Optimization of electrical energy use conditions.

“pk kumkol resources” jsc

ASCAPC of the “PetroKazakhstan Kumkol Resources” JSC is an automatic information source for commercial accounting of electric power and capacity. The...

AUTOMATED SYSTEM OF COMMERCIAL ACCOUNTING OF ELECTRIC ENERGY OF THE “PETROKAZAKHSTAN KUMKOL RESOURCES” JSC

| Customer: | “PetroKazakhstan Kumkol Resources” JSC |

| Implementation year: | 2007 – 2015 |

Immensity

Kyzylordinskaya oblast. Kumkol oil and gas field.

Scope of works and services rendered

The company professionals have performed the development of design and estimate documentation, supply of equipment, performed the construction and assembly and pre-commissioning activities.

Core of the project

ASCAPC of the “PetroKazakhstan Kumkol Resources” JSC is an automatic information source for commercial accounting of electric power and capacity. The system generates the data base of commercial accounting for energy generation and consumption by each record point, calculates the actual balance of production and consumption of electrical energy as well as provides the unbiased information for management of distribution of electricity and power.

Project unicity

ASCAPC of the “PetroKazakhstan Kumkol Resources” JSC was put in commercial operation and registered in the Register of electric power fiscal metering system of the wholesale electricity market of the Republic of Kazakhstan.

The long term of the project implementation was conditioned by the reason that the system implementation has been performed in several steps. First power facilities of the Kumkol oil-gas field were equipped in 2007, after which the Customer having assessed the advantages of operation with new system annually automatizes the new projects under construction.

Obtained result

The current system has enables the Customer to provide:

- The acquisition and delivery of information according to regulations, processing and issue of ASCAPC information in real time to the “PetroKazakhstan Kumkol Resources” JSC personnel as well as acquisition and delivery of information upon the request at all times;

- Obtaining of reliable and legitimate electricity metering in each record point using measuring devices;

- Enhanced accuracy of commercial accounting of electrical energy in record points using advanced energy accounting meters and application of digital technology of measurements, data acquisition and processing;

- Calculation of electrical energy balance for entire enterprise and by separate power facilities;

- Calculation of electrical energy losses in electric main using the ASCAPC data;

- Optimization of electrical energy use conditions.

|

Год |

Заказчик |

Описание |

|---|

Текущие проекты:

|

2014 |

АО «Озенмунайгаз» |

Внедрение интеллектуальных станций управления штангово-глубинн |

|

2014 |

АО «Электровоз курастыру зауыты» |

Поставка оборудования АСКУЭ для электровозов |

|

2013 – 2014 |

АО «НК «КТЖ» |

Внедрение Микропроцессорно |

|

2012 – 2015 |

АО «Транстелеком» |

Внедрение Автоматизированн |

|

2012 – 2014 |

ALSTOM (Франция) |

Поставка оборудования АСКУЭ для электровозов |

|

2012 – 2014 |

ТОО «Караганды Жарык» |

Внедрение АСКУЭ 0,4кВ г.Караганда (175 тыс.точек учета, 1500 ТП) |

|

2012 – 2014 |

АО «ПетроКазахстан Кумколь Ресорсиз» |

Расширение АСКУЭ в связи со строительством ПС 110/10кВ Кумколь-4, Кумколь-5 |

|

2012 – 2014 |

АО «НК «Казахстан Темир Жолы» |

Сервисное обслуживание АСКУЭ в 17 филиалах АО «НК «КТЖ»: - Астанинская, Екибастузская, Павлодарская, Кокшетауская, Жана-Есильская, Кустанайская, Атбасарская, Карагандинская, Агадырская, Шымкенсткая, Сарышаганская, Актобинская, Алматинская, Жамбылсая, Семейская, Уштобинская, Шусская дистанции электроснабжения Поддержание работоспособност |

Основные реализованные проекты TNS-INTEC:

|

2013 – 2014 |

АО «КазТрансОйл» |

Разработка и внедрение Систем локальной автоматики котельной и пункта подогрева нефти НПС им.Касымова (Атырау) |

|

2013 |

АО «НК «Казахстан Темир Жолы» |

Внедрение АСКУЭ пяти филиалов АО «НК «КТЖ»: Уральская, Атырауская, Мангыстауская, Кызылординская, Шалкарская дистанции электроснабжения |

|

2012 – 2013 |

ТОО «Карагандинская региональная энергетическая компания» |

Разработка и внедрение АСКУЭ |

|

2012 |

АО «Павлодарская распределительна |

Проектирование АСКУЭ |

|

2012 |

АО «НК «Казахстан Темир Жолы» |

Внедрение АСКУЭ пяти филиалов АО «НК «КТЖ»: Алматинская, Уштобинская, Семейская, Жамбылская, Шуская дистанции электрснабжения |

|

2012 |

АО «НК «Казахстан Темир Жолы» |

Сервисное обслуживание АСКУЭ в 10 филиалах АО «НК «КТЖ»: - Астанинская, Екибастузская, Павлодарская, Кокшетауская, Жана-Есильская, Кустанайская, Атбасарская, Карагандинская, Агадырская дистанции электроснабжения Поддержание работоспособност |

|

2012 |

АО «Тургай-Петролеу |

Разработка проекта и внедрение АСКУЭ ПС 110/6кВ Кумколь-7 |

|

2011 |

АО «ПетроКазахстан Кумколь Ресорсиз» |

Разработка проекта, аттестация техно-рабочего проекта и внедрение 2-го этапа АСКУЭ |

|

2010 |

ТОО «Корпорация Казахмыс» |

Разработка проекта и внедрение 1-й очереди АСКУЭ |

|

2009 – 2011 |

Чжучжоуский электровозострои |

Поставка оборудования АСКУЭ для электровозов |

|

2009 |

АО «Тургай-Петролеу |

Внедрение АСКУЭ |

|

2008 |

АО «Тургай-Петролеу |

Разработка проекта АСКУЭ |

|

2008 – 2009 |

АО «Локомотив» |

Опытно-конструкт |

|

2007 |

АО «ПетроКазахстан Кумколь Ресорсиз» |

Разработка проекта, аттестация техно-рабочего проекта и внедрение АСКУЭ |

|

2006 – 2009 |

АО «Локомотив» |

Внедрение АСКУЭ-ЦТ объектов, ввод в промышленную эксплуатацию |

|

2008 – 2009 |

АО «НК «Казахстан Темир Жолы» |

Внедрение АСКУЭ филиалов АО НК «Казакстан темiр жолы» ДЭ: Павлодар, Екибастуз, Агадырь, Атбасар, Кустанай, Жана-Есиль, Кокшетау. Ввод в промышленную эксплуатацию |

|

2006 – 2007 |

АО «Астана-Теплотра |

Проектирование Автоматизированн |

|

2005 – 2006 |

АО «НК «Казахстан Темир Жолы» |

Разработка и аттестация техно-рабочих проектов 16 дистанций электроснабжения (всего в АО «НК «КТЖ» 22 дистанции электроснабжения |

|

2005 |

Канала имени Каныша Сатпаева |

Разработка и аттестация техно-рабочего проекта внедрения АИИС КУЭ (Автоматизирован |

|

2004 – 2005 |

АО «КазТрансОйл» субподряд |

Реконструкция пускорегулирующе |

|

2004 |

АО «Локомотив» |

Разработка и аттестация техно-рабочих проектов внедрения АСКУЭ-ЦТ объектов |

|

2002 – 2003 |

АО «УзеньМунайГаз» |

Автоматизированн |

|

2001 – 2003 |

АО «КазТрансОйл» |

Система телемеханики магистральных нефтепроводов (разработка проекта и внедрение) |

|

2001 |

АО «КОКШЕТАУЭНЕРГО» |

Внедрение АСКУЭ и ИСУП |

CONTACTS

HOW TO REACH US

ORDER A CALL

Utegen Batyr street, 76A

NEWS

Software has been developed at the State Institution "Казселзащита" and "ДЧС".

At present, stage I has been completed, within the framework of which - 2 lake stations, 2 focal stations, 3 channel stations, and 3 dam stations on the rivers Ulken and Kishi Almaty have

...Kazakhstani international exhibition on electric energy took place in Almaty

ADDRESS

Almaty, Auezov district,

Str. Utegen Batyr, 76A

contacts

sales department

directories

REQUISITES

Акмолинская область, г. Ерейментау,

ул.Карасу,2а

г. Алматы, ул.Утеген батыра, дом 76а

факс: +7 727 277 35 17